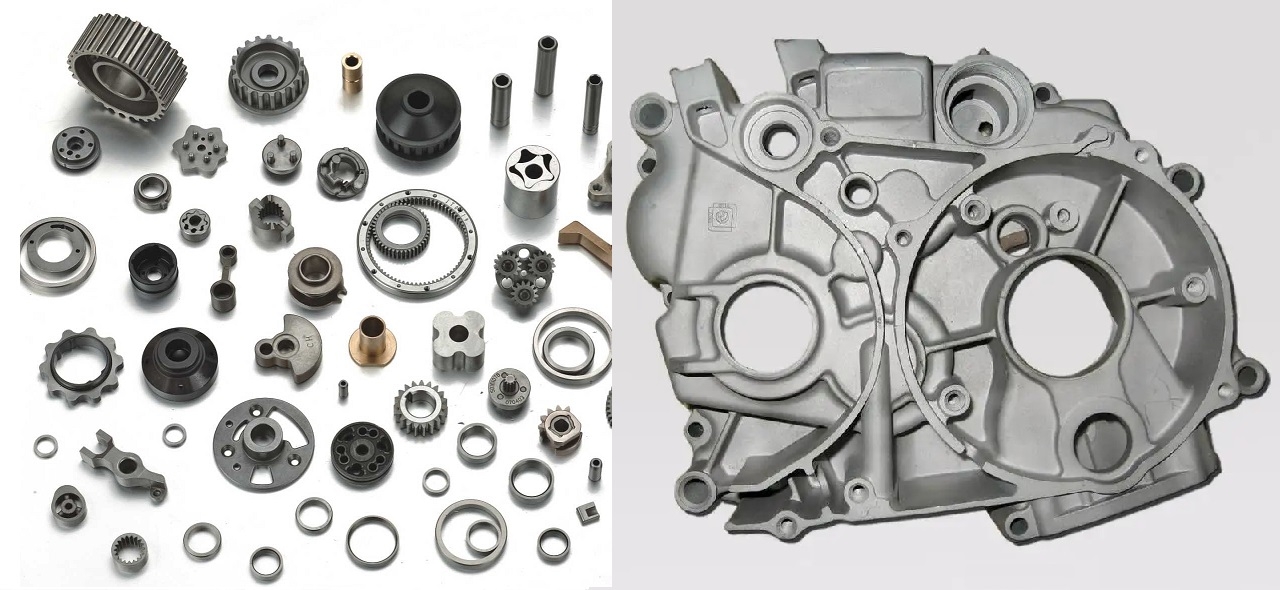

Ukhetho phakathi komgubo wesinyithi kunye ne-die casting ihlala ingumbuzo wenxalenye yobungakanani okanye iimfuno zezinto eziphathekayo kunoqoqosho.Izinto eziqhelekileyo ezisetyenziselwa ukuphosa ii-alloys ze-aluminium, ii-alloys ze-magnesium kunye ne-zinc alloys, kunye ne-copper alloy die castings nazo zisetyenziselwa umlinganiselo omncinci.Ngenxa yeqondo eliphezulu lokunyibilika kwe-ferroalloy kunye nensimbi engenasici, inkqubo ye-metallurgy powder kufuneka isetyenziswe.

Xa kuthelekiswa namalungu esinyithi enziwe ngomgubo wesintu, iinxalenye zokubumba iinaliti zentsimbi, imilinganiselo yeendawo zokuphosa ifa inokuba yinto enye okanye ibe nkulu kakhulu.Xa izinto eziphambili zifunwa, kulungele ngakumbi ukusebenzisa inkqubo ye-powder metallurgy.Umzekelo, u-1: amandla aphezulu kakhulu, ukomelela kwe-iron-based sintered alloys ingaphezulu ngokuphindwe kathathu kunolo lweealloyi zokufa.I-2: Ukumelana nokunxiba okuphezulu kunye nokusebenza okuphezulu kokunciphisa i-friction, enokuthi ixazululwe nge-iron-based based and copper-based sintered alloys efakwe ngeoli yokuthambisa.I-3: Ubushushu obuphezulu bokusebenza, obunokulungiswa nge-iron-based and copper-based sintered alloys.I-4: Ukumelana nokubola, i-alloy esekwe kwi-sintered alloy kunye ne-sintered steel stainless steel inokuhlangabezana neemfuno

Phakathi komgubo wesinyithi kunye ne-die casting, i-zinc die castings inokuthi ithathe indawo yeemveliso zesinyithi esekwe kwintsimbi xa ubushushu bokusebenza bungekho ngaphezulu kwe-65 °C kwaye kufuneka amandla aphakathi.Ezi nkqubo zimbini ziyafana ngokuchaneka kwe-dimensional kunye nesidingo somatshini.Kodwa malunga neendleko zezixhobo kunye noomatshini, i-powder metallurgy ihlala inenzuzo ngakumbi.

Ixesha lokuposa: Sep-26-2022