Renewable Design for Electric Drill Parts - Custom musical instrument powder metallurgy structural parts – Jingshi

Renewable Design for Electric Drill Parts - Custom musical instrument powder metallurgy structural parts – Jingshi Detail:

Product Description

Material Details: Iron Powder, iron alloy powder, Stainless Steel, Cooper, Steel, Iron, Alloy steel(C, Sn, Zn).

Max Density: 6.0 g/cm2~6.9 g/cm2,

Production Process: Mixing Powder-Powder Compacting-Sintering-Shaping-Machining-Surface Finish.

Surface Treatment: Machining, Oil Immersion, Steam Oxidation, Electroplate, Surface Blued.

Standard: DIN, JIS, ASTM, GB.

Application: Domestic electric, Electronic machine, Official business machines, Automobiles.

Inner Packaging: Anti-rust plastic film; Vacuum plastic bags.

Outer Packaging: Hard carton; Wooden case; Wood pallet.

Powder metallurgy use metal powder as raw material, through forming and sintering, manufacturing metal materials, composite materials and various types of products.Powder metallurgy technology can be directly made into porous, semi-compact or full-compact materials and products, such as Auto parts, Compressor spare parts.

Production process: mixed powder - powder compaction - sintering - molding - processing - surface treatment

Powder metallurgy OEM Structural Parts:

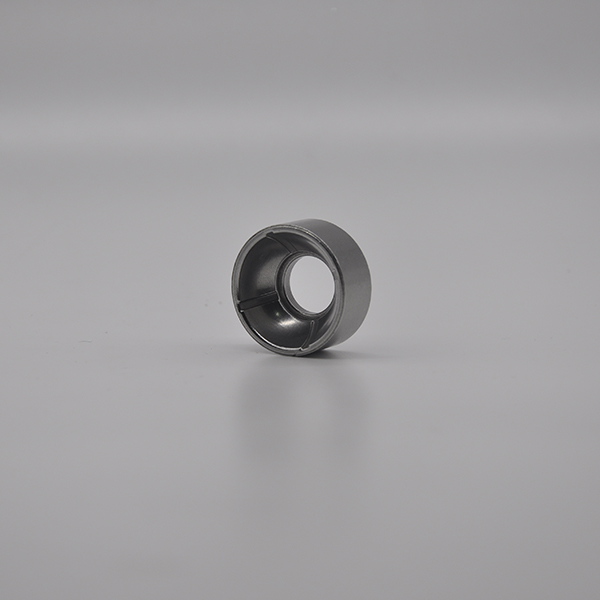

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Renewable Design for Electric Drill Parts - Custom musical instrument powder metallurgy structural parts – Jingshi , The product will supply to all over the world, such as: Iran, Manchester, Karachi, Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!