Hmoov metallurgy(PM) yog ib lo lus hais txog ntau txoj hauv kev uas cov ntaub ntawv lossis cov khoom tsim los ntawm cov hmoov hlau.Cov txheej txheem PM tuaj yeem zam, lossis txo qis heev, qhov yuav tsum tau siv cov txheej txheem tshem tawm cov hlau, yog li txo cov txiaj ntsig poob hauv kev tsim khoom thiab feem ntau ua rau cov nqi qis dua.

Nws yog dav siv hauv kev lag luam rau cov cuab yeej ntawm ntau hom thiab thoob ntiaj teb ~ 50,000 tonnes / xyoo (t / y) yog tsim los ntawm PM.Lwm cov khoom muaj xws li sintered lim, porous roj-impregnated bearings, hluav taws xob tiv tauj thiab cov cuab yeej pob zeb diamond.

Txij li thaum lub advent ntawm industrial ntau lawm-scale hlau hmoov-raws li additivemanufacturing (AM) nyob rau hauv lub 2010s, xaiv laser sintering thiab lwm yam hlau AM txheej txheem yog ib tug tshiab qeb ntawm kev lag luam tseem ceeb hmoov metallurgy daim ntaub ntawv.

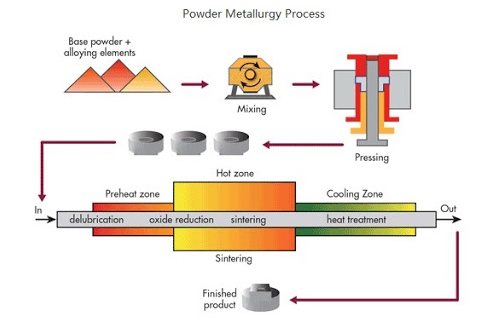

Cov hmoov metallurgy xovxwm thiab sinter txheej txheem feem ntau muaj peb kauj ruam yooj yim: hmoov blending (pulverisation), tuag compaction, thiab sintering.Compaction feem ntau yog ua nyob rau hauv chav tsev kub, thiab lub siab-kub txheej txheem ntawm sintering feem ntau yog ua nyob rau hauv atmospheric siab thiab nyob rau hauv ua tib zoo tswj cov huab cua muaj pes tsawg leeg.Kev xaiv thib ob xws li npib lossis kev kho cua sov feem ntau ua raws li kom tau txais cov khoom tshwj xeeb lossis kev ua kom zoo dua qub (los ntawm WIKIPEDIA)

Post lub sij hawm: Apr-24-2020